All of our vibratory bowl liners come with a 12-month warranty.

Rosler –Walther Trowal – Ceratex – Sharmic – William Boulton – Acton Finishing – SWECO

Why choose the Vibratory Bowl Relining Centre?

Vibrating bowls, deburring machines, troughs, metal finishing machines, centrifugal machines and more, we are the ideal place to repair your worn linings. We are able to reline almost any vibratory bowl deburring finishing machine with wear resistant polyurethane. Over the past 25 years, we have created moulds that allow us to accurately mould replacement liners that are superior to sprayed and rubber linings.

12 month warranty on all relines

Upto 50% cheaper then the price of an OEM reline

All coatings are moulded with high performance polyurethane using steel moulds (NON SPRAYED)

Complete repair service for damaged bowls

More than 25 years of experience in the repair and relining of vibratory finishing machines

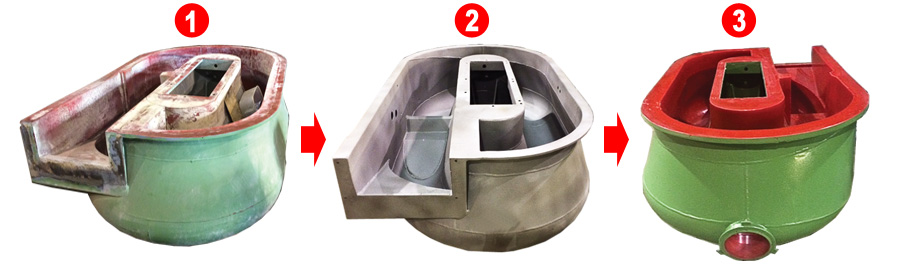

The process of replacing the worn liner consists of:

Remove the old worn liner

Abrasive blast process to remove all traces of the existing coating and remove rust / old paint from the outside of the bowl

Inspect the bowl for damage and cracks, etc. (If a crack is found, we will send you an image and make a repair if necessary)

Suspend a steel mould inside the bowl and fill the cavity with a very wear-resistant polyurethane

Place the bowl in the oven to cure the cast polyurethane

Mould doors / shutters and chutes, etc.

Demoulding and inspection of the new liner

Paint the outside of the bowl so that it comes back to you like new